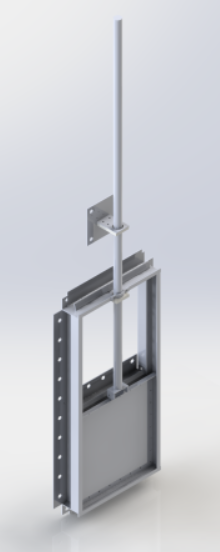

In the realm of industrial wastewater treatment, sludge scrapers play a vital and often understated role. Positioned strategically within sedimentation tanks and clarifiers, these unassuming components are integral to maintaining the efficiency and integrity of treatment systems. Operating with precision, sludge scrapers are equipped with blades or arms that methodically traverse the tank floor. Their orchestrated movement guides settled solids, commonly referred to as sludge, towards designated collection points. This meticulous removal process is pivotal in preventing the accumulation of sludge, which if left unchecked, can hinder processes and compromise the overall effectiveness of the treatment system. By ensuring a consistent removal of sludge, these scrapers contribute significantly to the quality of treated water and the seamless operation of industrial wastewater treatment facilities.

The significance of sludge scrapers lies in their ability to mitigate potential disruptions within industrial wastewater treatment processes. Excessive sludge buildup can lead to reduced tank capacity, hindered treatment efficiency, and undesirable odors. Through a range of operational methods, from manual control to automated precision, sludge scrapers demonstrate not only their reliability but also their critical role in preserving the operational continuity of industrial wastewater treatment facilities. As essential cogs in the machinery of water treatment, these unobtrusive yet indispensable components ensure that wastewater treatment remains both effective and consistent in industrial contexts.